Hawkeye

(An industrial IOT product)

Hawkeye is the ultimate AI-based IIoT product that revolutionises industrial processes, boosting production efficiencies and optimising asset management. With real-time machine connectivity, visual dashboards, AI-assisted analysis, improvement suggestions, and sustainable systems, Hawkeye empowers your industry with cutting-edge technology for unparalleled success.

Exhausted from managing employees performance manually?

Try Hawkeye For Free!

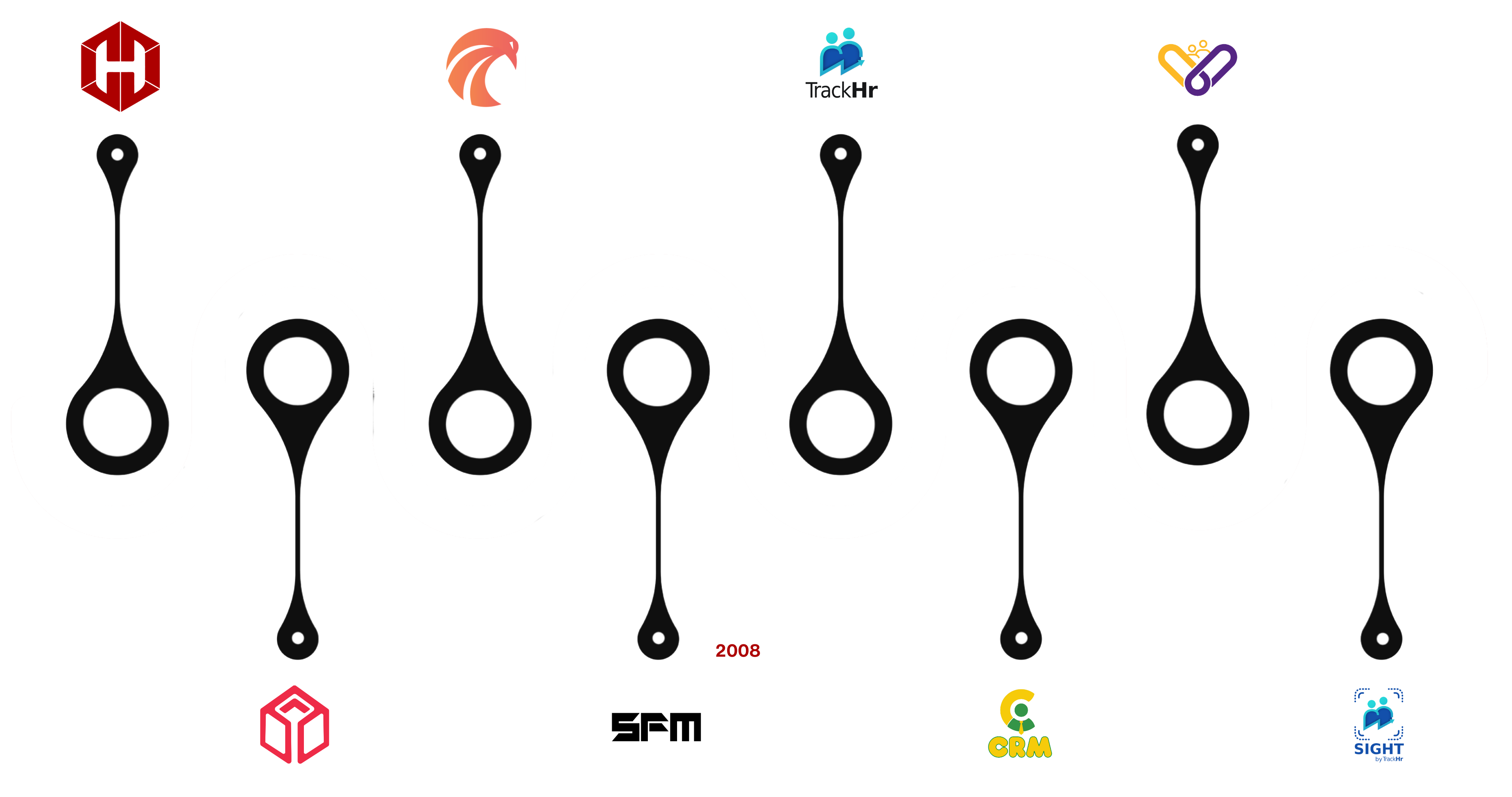

Our Clients

Hawkeye

At Hex Business Innovations, we don’t just offer software — we deliver complete visibility, accountability, and efficiency across your entire business.

Seamless Plug -and- Play Connectivity

Informative Machine Display Unit (M.D.U)

Efficient Assets Management

Live Production Perfromance On Mobile

Experience the power of remote monitoring with our mobile platform, enabling real-time access to shop floor performance from anywhere in the world. Utilizing cutting-edge cloud technology, you can effortlessly stay connected to your production operations on the go. Monitor live production data, track performance metrics, and gain valuable insights in real time, all from the convenience of your mobile device. Stay in control and make informed decisions to optimize productivity, regardless of your physical location. Embrace the freedom of remote monitoring and unlock the true potential of your shop floor with our mobile platform.

Simplify your asset management process by consolidating all your assets onto a single Hawkeye platform. From machine operators and supervisors to materials and more, Hawkeye seamlessly connects all relevant departments and teams. With the added convenience of mobile device integration and Andon systems, collaboration and communication among teams become effortless. Experience enhanced efficiency and optimize your asset management workflow with Hawkeye’s comprehensive platform.

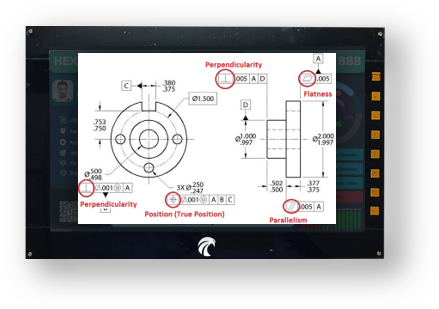

Introducing our Informative Machine Display Unit (M.D.U), a powerful tool that broadcasts and displays real-time information and documents seamlessly through the Hawkeye platform. With M.D.U., you can effortlessly showcase vital details such as part drawings, process flow diagrams, job asset allocations, and more. Stay informed and keep your teams up to date with critical information, improving operational efficiency and facilitating smooth workflows. Experience the power of real-time data visualization and document sharing with M.D.U integrated into the Hawkeye platform.

Experience the power of remote monitoring with our mobile platform, enabling real-time access to shop floor performance from anywhere in the world. Utilizing cutting-edge cloud technology, you can effortlessly stay connected to your production operations on the go. Monitor live production data, track performance metrics, and gain valuable insights in real time, all from the convenience of your mobile device. Stay in control and make informed decisions to optimize productivity, regardless of your physical location. Embrace the freedom of remote monitoring and unlock the true potential of your shop floor with our mobile platform.

Experience the power of remote monitoring with our mobile platform, enabling real-time access to shop floor performance from anywhere in the world. Utilizing cutting-edge cloud technology, you can effortlessly stay connected to your production operations on the go. Monitor live production data, track performance metrics, and gain valuable insights in real time, all from the convenience of your mobile device. Stay in control and make informed decisions to optimize productivity, regardless of your physical location. Embrace the freedom of remote monitoring and unlock the true potential of your shop floor with our mobile platform.

Simplify your asset management process by consolidating all your assets onto a single Hawkeye platform. From machine operators and supervisors to materials and more, Hawkeye seamlessly connects all relevant departments and teams. With the added convenience of mobile device integration and Andon systems, collaboration and communication among teams become effortless. Experience enhanced efficiency and optimize your asset management workflow with Hawkeye’s comprehensive platform.

Introducing our Informative Machine Display Unit (M.D.U), a powerful tool that broadcasts and displays real-time information and documents seamlessly through the Hawkeye platform. With M.D.U., you can effortlessly showcase vital details such as part drawings, process flow diagrams, job asset allocations, and more. Stay informed and keep your teams up to date with critical information, improving operational efficiency and facilitating smooth workflows. Experience the power of real-time data visualization and document sharing with M.D.U integrated into the Hawkeye platform.

Experience the power of remote monitoring with our mobile platform, enabling real-time access to shop floor performance from anywhere in the world. Utilizing cutting-edge cloud technology, you can effortlessly stay connected to your production operations on the go. Monitor live production data, track performance metrics, and gain valuable insights in real time, all from the convenience of your mobile device. Stay in control and make informed decisions to optimize productivity, regardless of your physical location. Embrace the freedom of remote monitoring and unlock the true potential of your shop floor with our mobile platform.

Graphical Target Monitoring

Instant Shop Floor Broadcast

Planned Maintenance Alerts

Experience the power of instant communication on the shop floor with our system. With just a click, critical information from the back office is instantaneously updated and broadcasted directly to the shop floor.Say goodbye to delays and miscommunication. With our instant broadcast system, critical information is disseminated instantly, allowing for agile responses and streamlined processes.

Our automated preventive maintenance system ensures timely maintenance with planned maintenance alerts. As soon as the predefined criteria are triggered, personnel in the back office and on the shop floor receive automated notifications.

Our system employs graphical target monitoring to effectively enforce performance improvements. By utilizing a graphical interface and target lines, we highlight current performance gaps and inefficiencies in a clear and visually intuitive manner.With this feature, you can easily identify areas where performance falls short of targets. The graphical representation enables quick and informed decision-making, as well as efficient allocation of resources to address the identified gaps.

Hawkeye

An industrial IOT product

Hawkeye

Hawkeye is the ultimate AI-based IIoT product that revolutionises industrial processes, boosting production efficiencies and optimising asset management. With real-time machine connectivity, visual dashboards, AI-assisted analysis, improvement suggestions, and sustainable systems, Hawkeye empowers your industry with cutting-edge technology for unparalleled success.

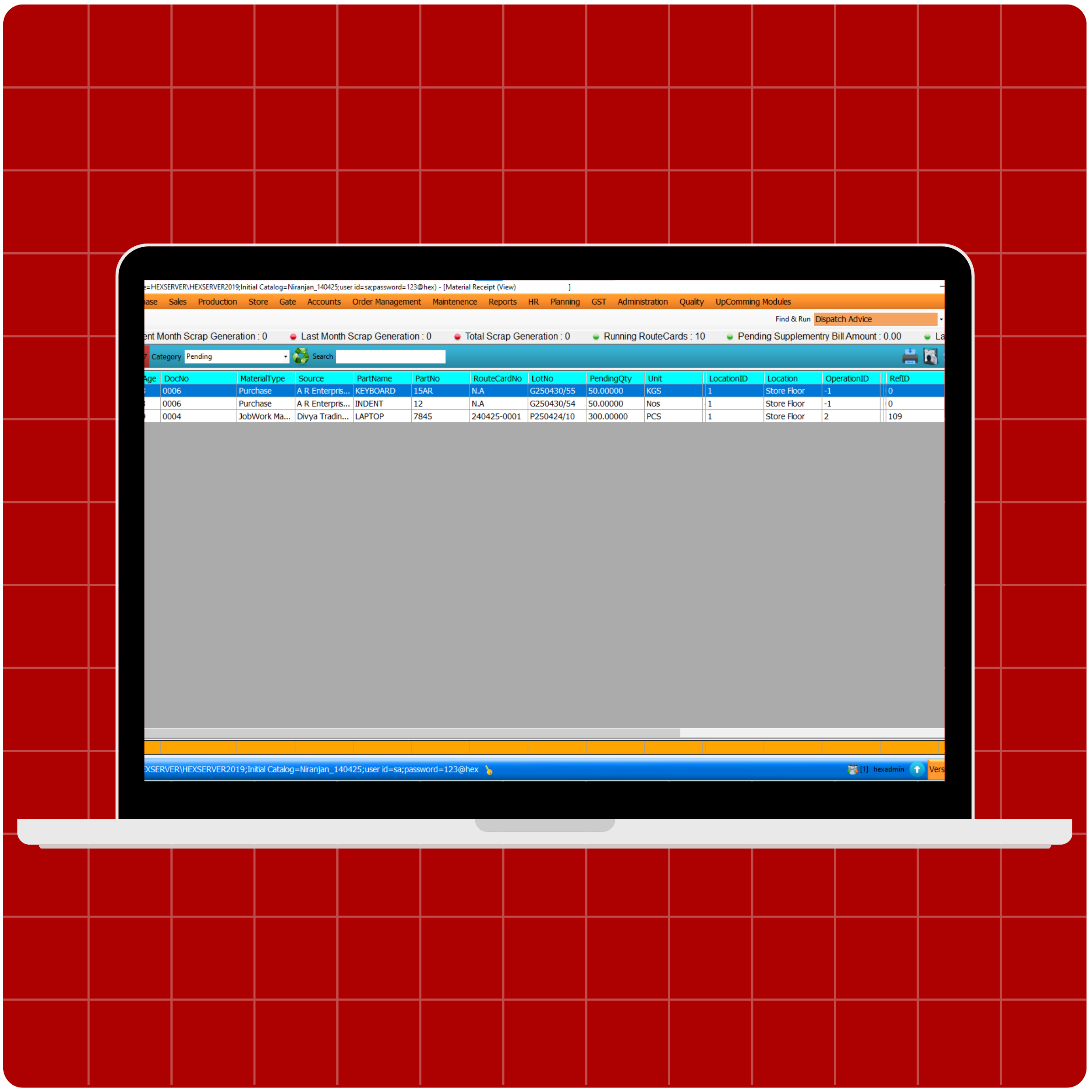

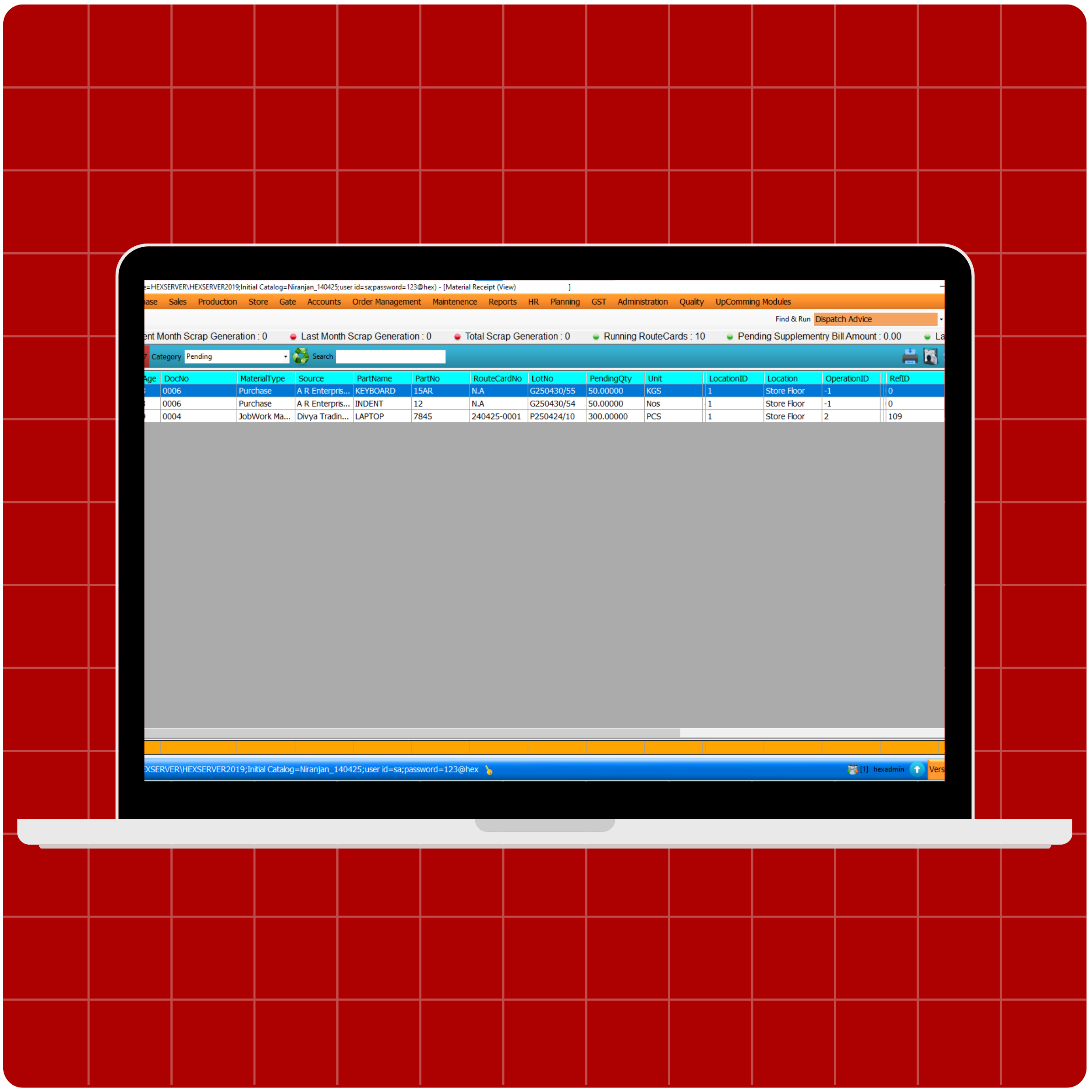

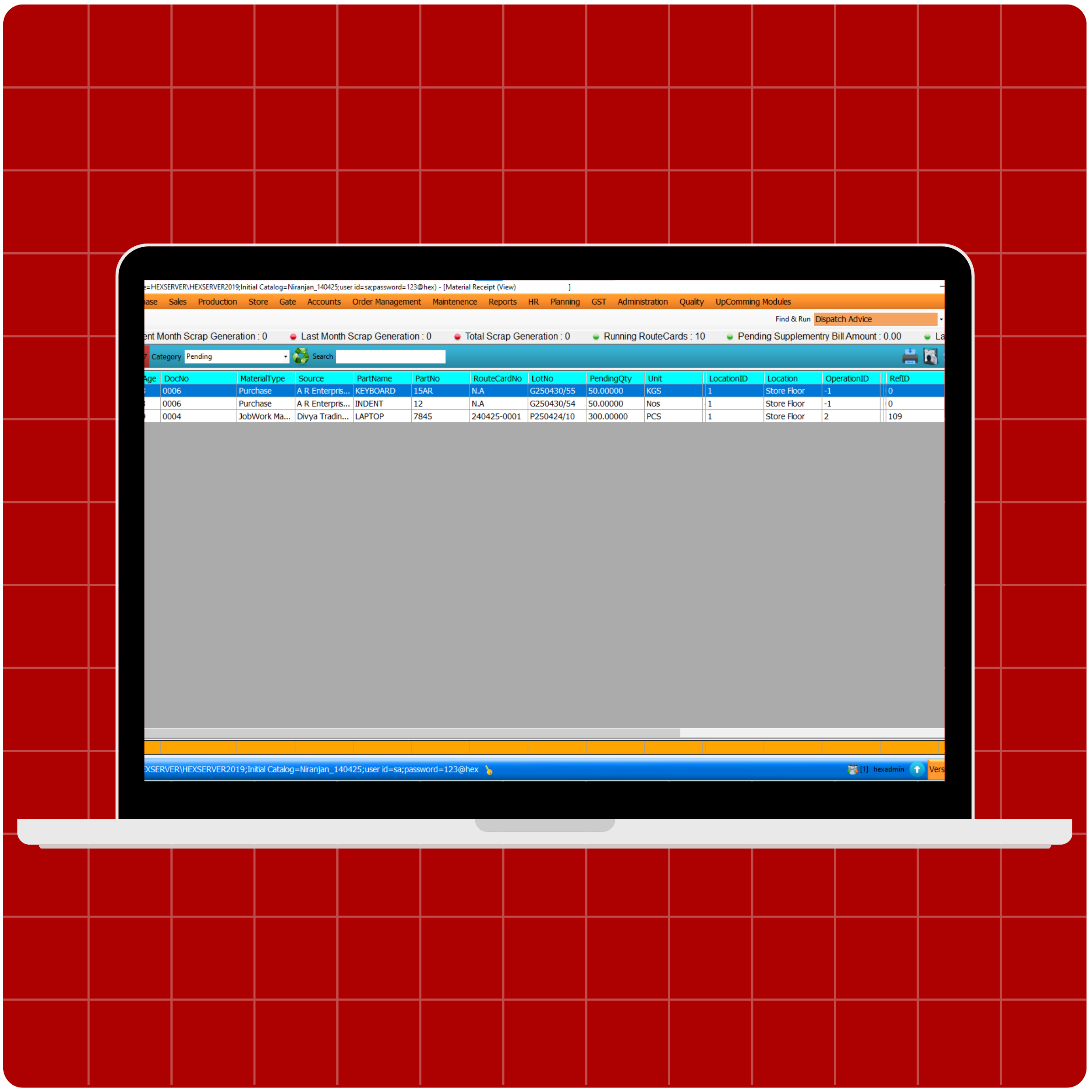

Introducing our IIoT-based Machine Display Unit, a hassle-free solution that connects and integrates your machines with the Hawkeye platform in just minutes. With its plug-and-play Wi-Fi connectivity, setup becomes a breeze, enabling you to start monitoring and optimizing your machines without any delays. Experience the convenience of seamless connectivity and unlock the full potential of your industrial operations with ease.

Simplify your asset management process by consolidating all your assets onto a single Hawkeye platform. From machine operators and supervisors to materials and more, Hawkeye seamlessly connects all relevant departments and teams. With the added convenience of mobile device integration and Andon systems, collaboration and communication among teams become effortless. Experience enhanced efficiency and optimize your asset management workflow with Hawkeye’s comprehensive platform.

Introducing our Informative Machine Display Unit (M.D.U), a powerful tool that broadcasts and displays real-time information and documents seamlessly through the Hawkeye platform. With M.D.U., you can effortlessly showcase vital details such as part drawings, process flow diagrams, job asset allocations, and more. Stay informed and keep your teams up to date with critical information, improving operational efficiency and facilitating smooth workflows. Experience the power of real-time data visualization and document sharing with M.D.U integrated into the Hawkeye platform.

Experience the power of remote monitoring with our mobile platform, enabling real-time access to shop floor performance from anywhere in the world. Utilizing cutting-edge cloud technology, you can effortlessly stay connected to your production operations on the go. Monitor live production data, track performance metrics, and gain valuable insights in real time, all from the convenience of your mobile device. Stay in control and make informed decisions to optimize productivity, regardless of your physical location. Embrace the freedom of remote monitoring and unlock the true potential of your shop floor with our mobile platform.

Say goodbye to inconsistencies and gain a clear picture of your entire shop floor with our real-time utilization reporting feature. By automating production data logging and reporting, we ensure accuracy and eliminate manual errors. Monitor the utilization of various assets, including manpower, machinery, and materials, all on a single integrated platform. Our system provides comprehensive insights into asset performance, enabling you to make informed decisions and optimize resource allocation. Experience the ease of monitoring and the power of accurate utilization reporting with our integrated platform, revolutionizing your production operations.

Never waste valuable time again with our accurate downtime monitoring feature. Receive instant alerts and detailed reasons for downtime occurrences, empowering you to take immediate and informed action. By identifying the root causes of downtime quickly, you can rectify issues promptly, minimizing production disruptions and maximizing productivity. Stay ahead of potential setbacks and keep your operations running smoothly with our comprehensive downtime monitoring system. Experience the power of real-time alerts and make every moment count in your production processes.

Our hidden capacity evaluation system utilizes advanced calculations of Overall Equipment Effectiveness (OEE) and adheres to TPM (Total Productive Maintenance) standards. Uncovering untapped efficiencies and hidden capacities, we provide valuable insights into your production operations. Identify areas for improvement, optimize equipment utilization, and boost productivity. Experience the power of data-driven decision-making to propel your business forward. Maximize your shop floor’s potential with our comprehensive evaluation system.

Our operating cost evaluation precisely assesses the actual costs incurred in your operations by analyzing utilization patterns and uncovering hidden wastages. By revealing the real cost of your operations, we provide invaluable insights into optimizing resource usage and reducing unnecessary expenses. Experience data-driven analysis to make informed decisions and enhance your operational efficiency. Discover the true cost of your operations and unlock opportunities for cost savings with our comprehensive evaluation system.

Introducing our real-time distress feature that minimizes communication delays and reduces resolution time. Our on-machine distress call mechanism directly notifies the concerned department, ensuring swift response and resolution. Say goodbye to unnecessary delays and improve operational efficiency. Experience the power of real-time distress notifications to address issues promptly and keep your operations running smoothly. Streamline your communication channels and resolve distress situations in no time with our efficient system.

Experience the power of instant quality control with our automated inspection alerts. Our system combines the inspection plan with live production floor data to provide real-time information on quality. Receive immediate alerts regarding inspection results, including rejection data and yield, directly from every machine.

With our MDU (Machine Display Unit), we enforce critical tasks such as distress calls and inspections to be addressed physically at the location itself, following the GEMBA methodology. By utilizing QR codes, we eliminate misinformation and resolution delays, ensuring accurate and efficient on-site operations.

Andon system provides up-to-date information on the status of the processes occurring on the shop floor and back offices through wireless means. It alerts employees immediately of any problems or deviations that occur, promoting faster decision-making and improved solutions.

Our system employs graphical target monitoring to effectively enforce performance improvements. By utilizing a graphical interface and target lines, we highlight current performance gaps and inefficiencies in a clear and visually intuitive manner.With this feature, you can easily identify areas where performance falls short of targets. The graphical representation enables quick and informed decision-making, as well as efficient allocation of resources to address the identified gaps.

Our automated preventive maintenance system ensures timely maintenance with planned maintenance alerts. As soon as the predefined criteria are triggered, personnel in the back office and on the shop floor receive automated notifications.

Experience the power of instant communication on the shop floor with our system. With just a click, critical information from the back office is instantaneously updated and broadcasted directly to the shop floor.Say goodbye to delays and miscommunication. With our instant broadcast system, critical information is disseminated instantly, allowing for agile responses and streamlined processes.